Tips for Measuring and Cutting Wood Accurately

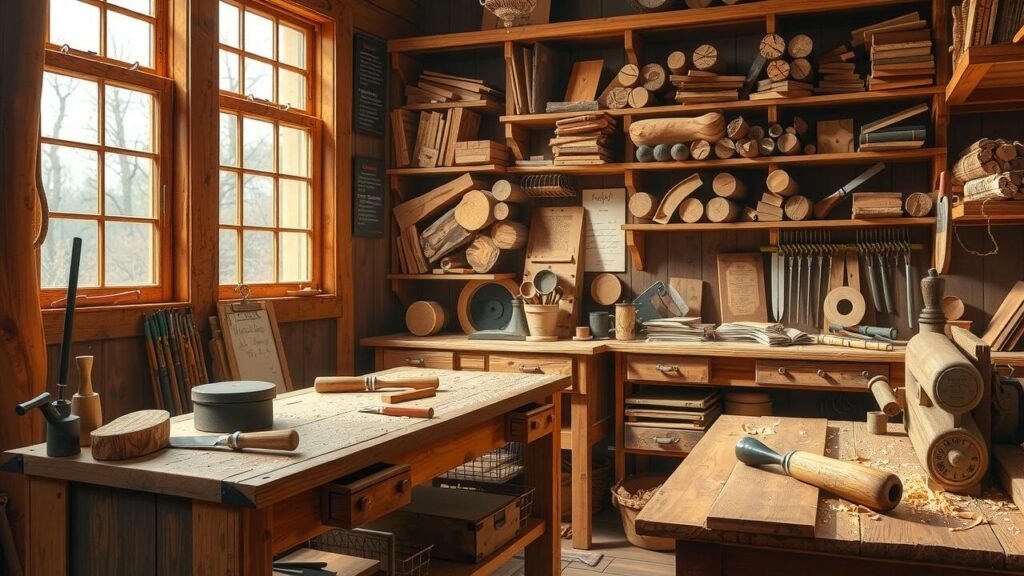

Start Building Even Without Fancy Tools

- Follow step-by-step instructions that don’t skip crucial details

- Build at your own pace and grow your skills project by project

- Cut down on costly do-overs with better planning and diagrams

Accurate measurements are crucial in woodworking to ensure that pieces fit together seamlessly. Start by using a reliable tape measure, and double-check your measurements before making any cuts. Mark cutting lines clearly with a pencil or a marking knife, as this will help maintain visibility during the cutting process. For additional precision, consider using a square to create perfect right angles, especially when working with joints. Remember to account for the thickness of the saw blade in your measurements to avoid any miscalculations.

When it comes to cutting wood, the right tools can greatly enhance accuracy. A circular saw is ideal for long, straight cuts while a miter saw allows for more precise angled cuts. Always support the wood properly to prevent any movement during cutting. Clamping your workpiece securely can also improve stability and ensure a cleaner cut. If you aim for a finer finish, using a table saw equipped with a fence can help maintain consistent widths across multiple pieces. Prioritize taking your time with these steps to achieve the best results.

Tools and Techniques for Precision

Achieving precision in woodworking hinges on using the right tools and techniques. A quality measuring tape, square, and calipers are essential for ensuring that all dimensions are accurate. A table saw and miter saw can provide clean and straight cuts, while a router allows for more detailed shaping. Employing stop blocks and clamps can further enhance cutting accuracy, minimizing the chances of error.

Incorporating techniques such as measuring twice before cutting can save time and resources. When working with plywood or thicker boards, using a guide can help maintain straight cuts, reducing the risk of splintering. Additionally, keeping blades sharp ensures cleaner cuts and minimizes wear on equipment. Embracing these practices fosters a disciplined approach, resulting in furniture components that fit seamlessly together.

Finishing Touches

Sanding is a crucial part of woodworking that enhances the final appearance of your piece. Begin with coarse-grit sandpaper to remove any rough spots or imperfections. Progressively use finer grits to achieve a smooth surface. Pay attention to the wood grain direction, sanding along it to prevent scratches. A power sander can save time, but hand sanding allows for more control and precision in tight areas.

Staining offers an opportunity to bring out the natural beauty of the wood. Choose a stain that complements the wood species and fits the desired aesthetic. Apply the stain evenly with a brush or cloth, following the grain for a uniform application. Allow it to sit for the recommended time before wiping off excess stain with a clean cloth. This finishing touch not only enhances the wood’s color but also protects the surface, ensuring your furniture lasts for years.

Techniques for a Professional Finish

Achieving a professional-looking finish requires meticulous attention to detail at every stage of the process. Start with sanding the wood using progressively finer grits. Begin with a coarser grit to remove any imperfections and rough surfaces. Gradually move to finer grits, ensuring that the surface feels smooth to the touch before applying any stain or finish. This step is crucial for creating a flat surface that allows finishes to adhere evenly.

Once sanding is complete, selecting the right stain and finish will significantly impact the overall appearance. Apply stain evenly with a brush or cloth, ensuring to follow the wood grain for a natural look. Allow it to penetrate for several minutes, then wipe off the excess to prevent blotching. After the stain dries, consider applying multiple coats of clear finish, such as polyurethane or varnish, to enhance durability and shine. Sand lightly between coats for the best results, promoting adhesion and a smoother surface.

16,000 Woodworking Plans In One Place

- Use exact cutting and materials lists to reduce waste and mistakes

- Build confidently even if you’re a beginner with basic hand tools

- Cut down on costly do-overs with better planning and diagrams

Safety Measures in Woodworking

Woodworking can be a rewarding experience, but it comes with inherent risks. Understanding basic safety measures is crucial for anyone working with tools and materials. Properly maintaining equipment reduces the risk of accidents. It is important to familiarize oneself with each tool’s operating procedures and potential hazards before starting a project.

Wearing appropriate safety gear is essential. Eye protection should be a priority to shield against flying debris. Earplugs can help mitigate the risks associated with prolonged noise exposure from power tools. Gloves are helpful when handling rough or heavy materials, but care is needed to ensure they do not become entangled in equipment. Awareness of one’s environment and following safety guidelines can create a safer workspace.

Essential Safety Gear for Woodworkers

Protecting oneself while working with wood is critical for any woodworker. Safety goggles are essential to shield eyes from sawdust and flying debris during cutting or sanding. Ear protection is also important, especially when using power tools that emit loud noise. A well-fitted dust mask can prevent inhalation of fine particles that are harmful to your lungs.

In addition to eye and ear protection, wearing gloves can provide a barrier against scrapes and cuts. It’s advisable to select gloves that offer a good grip while allowing dexterity for handling tools. Non-slip footwear is another crucial element, helping to prevent accidents in a workshop where wood shavings or other materials may create a slippery environment. By investing in proper safety gear, woodworkers can focus on their craft while minimizing risks.

FAQS

What are woodworking furniture plans?

Woodworking furniture plans are detailed blueprints or guides that provide instructions on how to build various types of furniture, including dimensions, materials needed, and step-by-step assembly processes.

Do I need advanced skills to follow woodworking furniture plans?

Not necessarily. Many woodworking plans cater to various skill levels, from beginners to advanced woodworkers. It’s important to choose plans that match your skill level and comfort with tools.

What tools do I need to get started with woodworking furniture plans?

Essential tools for woodworking include a saw, measuring tape, square, drill, and various hand tools. As you advance, you may want to invest in additional tools for precision and efficiency.

How can I ensure accurate measurements when building furniture?

To ensure accurate measurements, always measure twice and cut once. Use a reliable measuring tape and a square to confirm your angles. Additionally, follow the instructions in your woodworking plans closely.

What safety gear should I wear while woodworking?

Essential safety gear for woodworking includes safety goggles, ear protection, a dust mask or respirator, and gloves. Always prioritize safety to prevent accidents and injuries while working with tools and materials.

Related Links

woodworking furniture plans

Easy Furniture Plans for Beginners: Tables, Benches, and Storage That Fit

Modern Furniture Plans: Clean Designs With Simple Joinery

Furniture Plans With Cut Lists: Save Time and Get Cleaner Results

Beginner Furniture Plans That Don’t Require Fancy Tools

How to Pick Furniture Plans That Match Your Tools and Skill Level

Furniture Plans That Use Standard Lumber Sizes (Less Waste, Less Stress)

Common Furniture Plan Errors: Measurements, Joinery, and Stability Fixes

DIY Furniture Plans: The Fastest Way to Build Something You’ll Keep

Best Beginner Furniture Builds: 7 Projects That Teach Real Skills

Detailed Blueprints That Guide Every Cut

- Follow step-by-step instructions that don’t skip crucial details

- Get new plans added regularly so you never run out of ideas

- Cut down on costly do-overs with better planning and diagrams