Finished Dimensions and Specifications

Start Building Even Without Fancy Tools

- Follow step-by-step instructions that don’t skip crucial details

- Build at your own pace and grow your skills project by project

- Cut down on costly do-overs with better planning and diagrams

Clear finished dimensions and specifications are essential for any woodworking project. These measurements guide woodworkers through the construction process. They provide a detailed overview of the desired size and layout of the final product, ensuring that everything fits together as intended. A good plan will include precise dimensions for each component, accounting for factors like joinery and material thickness.

Incorporating specifications such as tolerances and grain direction can significantly enhance the quality of the finished piece. These details contribute to aesthetic appeal and structural integrity. Woodworkers benefit from understanding the overall design intent, especially when it comes to fitting components together. Proper dimensions help prevent costly mistakes and minimize material waste, making the project more efficient and enjoyable.

Measuring for Accuracy and Fit

Precision in woodworking projects hinges on accurate measurements. Each cut and joint relies on the dimensions provided in your plans. A good set of woodworking plans not only outlines the final measurements but also details how to achieve those specifications during the building process. This includes step-by-step instructions that guide woodworkers through the measuring technique, ensuring that each component fits together seamlessly for structural integrity and visual appeal.

Checking measurements frequently throughout the project can prevent costly errors. Woodworkers should use reliable measuring tools, such as calipers, tape measures, and squares, to ensure that every part is cut to the precise size. Supplemental information, such as tolerance levels and fitting adjustments, is crucial. This allows for any variances in material or environmental factors, ensuring a sturdy and well-fitted result that enhances the enjoyment and functionality of the final piece.

Safety Guidelines

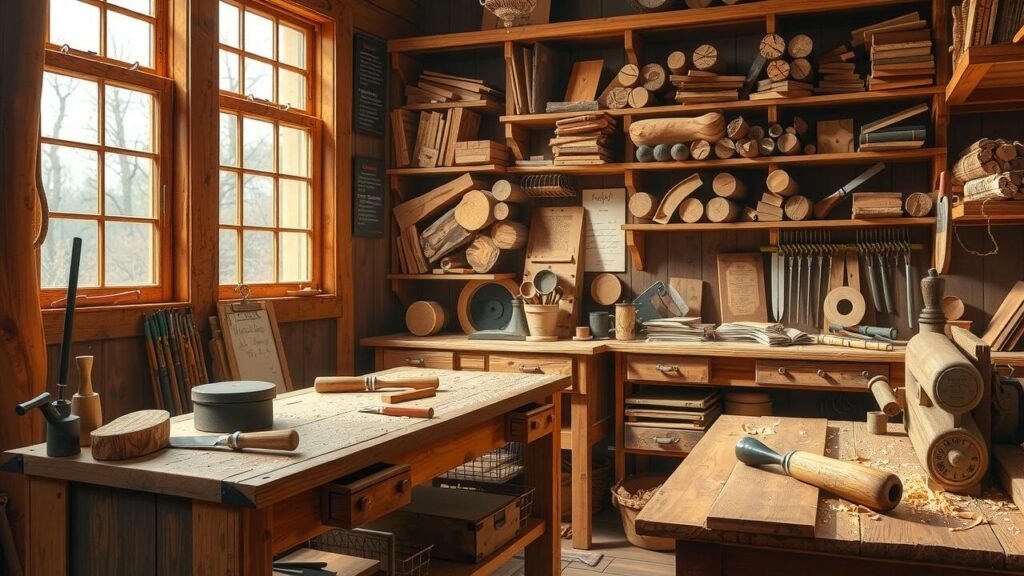

Ensuring a safe working environment is essential for any woodworker, regardless of experience level. Following established safety guidelines minimizes the risk of accidents and injuries. Always wear appropriate personal protective equipment, such as safety goggles, ear protection, and dust masks. Keeping your workspace clean and organized also contributes to a safer environment. Tools should be maintained regularly to prevent malfunctions that could lead to dangerous situations.

Incorporating safety practices into your woodworking routine can significantly enhance your overall craftsmanship. Familiarizing yourself with the operation of each tool is vital, as using equipment incorrectly can lead to serious harm. Additionally, never bypass safety features on machines; these are designed to protect you. Always remain focused and avoid distractions while working, as attention lapses can have severe consequences. Instilling these habits will create a culture of safety in your workshop.

Preventing Accidents in Your Workshop

Creating a safe working environment is crucial for any woodworker. First and foremost, personal protective equipment (PPE) should be worn at all times to shield against flying debris, loud noises, and harmful dust. Safety glasses, ear protection, and dust masks can significantly reduce the risks associated with woodworking projects. Additionally, proper attire like fitted clothing and non-slip footwear helps in preventing accidents that may occur due to loose garments or poor footing.

Maintaining a clean and organized workspace plays a key role in accident prevention. Tools and materials should be arranged logically to minimize hazards while working. Regularly checking that tools are in good condition prevents malfunctions during use. Understanding how to operate each tool safely is essential. Thoroughly reviewing and following the manufacturer’s guidelines can help woodworkers avoid common pitfalls and maintain a safer workshop atmosphere.

16,000 Woodworking Plans In One Place

- Use exact cutting and materials lists to reduce waste and mistakes

- Build confidently even if you’re a beginner with basic hand tools

- Cut down on costly do-overs with better planning and diagrams

Accessibility of Plans

The availability of woodworking plans in various formats enhances the experience for woodworkers of all skill levels. Digital downloads offer immediate access. These plans can be printed out or viewed on tablets and smartphones. The flexibility allows woodworkers to choose the format that best suits their needs. Many websites offer PDF files, which can maintain high-quality images and clear instructions. Some platforms also provide interactive formats for a more engaging experience.

In addition to conventional formats, some plans come with video tutorials or supplementary materials. These resources can help clarify complicated steps. Having multiple forms of instruction can be particularly beneficial for beginners who may need visual guidance. Accessibility in terms of content ensures that woodworkers can easily follow along and complete projects without feeling overwhelmed. Making these plans readily available contributes to a more enjoyable and successful woodworking journey.

Formats That Suit Every Woodworker

Woodworking plans come in various formats, catering to the diverse preferences of woodworkers. Digital downloads are popular, providing instant access to diagrams, measurements, and instructions. PDF files are common due to their universal compatibility, allowing for easy viewing and printing on any device. Some plans also come in specialized software formats that enable interactive features, such as 3D modeling. These tools help users visualize the final product and make necessary adjustments before starting the physical crafting process.

Printable plans are another option, offering a tangible copy that can be easily referenced in the workshop. These may include scaled drawings that can be directly traced onto materials. Additionally, some woodworkers prefer mobile-friendly formats. Apps designed for tablets and smartphones allow for on-the-go access, ensuring that users have their plans handy wherever they work. This accessibility enhances the overall woodworking experience, enabling enthusiasts at various skill levels to find the right plan that suits their needs.

FAQS

What are some essential elements that a good woodworking plan should include?

A good woodworking plan should include finished dimensions, specifications, detailed measurements for accuracy and fit, safety guidelines, and accessibility in various formats.

How can I ensure that my woodworking project fits accurately?

To ensure accuracy and fit, carefully measure all components according to the plan, double-check your measurements, and make adjustments as necessary before cutting any materials.

What safety guidelines should I follow while working on woodworking projects?

Always wear appropriate personal protective equipment (PPE), keep your workspace organized, use tools correctly, and be aware of your surroundings to prevent accidents.

Are downloadable woodworking plans available in different formats?

Yes, many downloadable woodworking plans are available in various formats, such as PDF, CAD, or even interactive digital formats, to accommodate different preferences and skill levels.

Where can I find reliable downloadable woodworking plans?

Reliable downloadable woodworking plans can be found on specialized woodworking websites, online marketplaces, or through woodworking communities and forums that share resources and recommendations.

Detailed Blueprints That Guide Every Cut

- Follow step-by-step instructions that don’t skip crucial details

- Get new plans added regularly so you never run out of ideas

- Cut down on costly do-overs with better planning and diagrams