Choosing the Right Finish for Different Materials

Start Building Even Without Fancy Tools

- Follow step-by-step instructions that don’t skip crucial details

- Build at your own pace and grow your skills project by project

- Cut down on costly do-overs with better planning and diagrams

Finishing techniques can greatly influence the appearance and functionality of craft show items. Each material often requires a specific type of finish to enhance its natural properties. For wood, an oil-based finish can penetrate deeply and highlight the grain, while water-based finishes offer a quicker drying time and lower odor. Metal pieces may benefit from galvanizing or a clear coat to prevent rust and preserve shine, while ceramics often call for a glaze or sealant that enhances color while ensuring durability.

Textiles, on the other hand, are best treated with fabric-specific products that maintain flexibility and softness. A permanent fabric spray can help protect against stains without compromising the drape. For paper or cardboard items, a polyurethane spray or a suitable varnish can provide a protective layer that resists tearing and moisture. Understanding how different finishes interact with various materials is crucial for achieving the desired look and longevity in your craft show offerings.

Material-Specific Finishing Tips

Wood items benefit from a variety of finishes that enhance their natural beauty and provide protection. For indoor wood crafts, a polyurethane or lacquer finish offers durability while allowing the grain to shine through. When working with outdoor projects, water-resistant finishes such as marine varnish are ideal for shielding against the elements. Always ensure the wood surface is sanded smooth before applying any finish to achieve an even coat and prevent peeling.

For fabric crafts, choosing the right finish is essential for maintaining the integrity of the material. A fabric sealant can protect items like tote bags or wall hangings from stains and moisture. Non-toxic fabric paints or dyes give long-lasting color while enabling washability. Before applying any finish, it’s important to prewash the fabric to remove any sizing or chemicals that could interfere with adhesion.

How to Apply Finishes Effectively

Preparation is key before applying any finish. Ensure the surface of the item is clean and free from dust or oils. Using fine sandpaper can smooth out imperfections, creating an ideal canvas for the finish. If necessary, wipe the surface with a damp cloth to remove any debris that may interfere with adhesion. Always allow the surface to dry completely before proceeding with the application.

When applying the finish, choose appropriate tools based on the product’s characteristics and your project. Brushes work well for detailed areas, while spray finishes provide a smooth, even coat without brush strokes. Be cautious with application technique; a consistent, thin layer is often more effective than a single heavy coat. Allow adequate drying time between layers to achieve the best results, and do not rush the process. Regular inspection during drying and curing will help catch any imperfections to be addressed later.

Best Practices for Application Techniques

Applying finishes requires careful preparation to achieve the best results. Begin by ensuring that the surface is clean and smooth. Sand any rough edges and remove dust with a soft cloth. This step helps the finish adhere better and creates a polished appearance. When using brushes, choose quality materials to avoid streaks. Work with even strokes to promote a uniform layer and minimize drips or pooling.

Using the right tools can greatly enhance the finish. For larger surfaces, foam rollers or sprayers can provide a smooth application, while finer brushes work well for detailed areas. Always apply in thin coats, allowing adequate drying time between layers. This practice not only improves durability but also achieves a professional look. Proper ventilation is essential when using any chemical-based finishes to ensure a safe and effective environment during the application process.

16,000 Woodworking Plans In One Place

- Use exact cutting and materials lists to reduce waste and mistakes

- Build confidently even if you’re a beginner with basic hand tools

- Cut down on costly do-overs with better planning and diagrams

Budget-Friendly Finishing Solutions

Finding affordable finishing solutions for craft show items requires a bit of creativity. An array of products is available that won’t break the bank. For wood projects, consider using inexpensive water-based varnishes. They provide a durable layer of protection and dry quickly, perfect for busy crafters needing to prepare multiple items. Many craft stores offer sales or bulk pricing on popular finishes, making it easier to stick to a budget while not sacrificing quality.

For fabric-based projects, look into DIY options like homemade fabric stiffeners made from glue and water. These can effectively enhance the appearance and durability of fabric items. Thrift stores or clearance racks can yield hidden gems, such as paints and glues, that can be repurposed for finishing. It’s important to explore local craft groups or online communities for tips and shared resources, which can help discover new techniques and products at lower prices.

Cost-Effective Options That Don’t Compromise Quality

There are several affordable finishes that can enhance the appearance and longevity of craft show items without straining your budget. Acrylic sealers provide a clear protective layer and are easy to apply, making them ideal for wood and canvases. Similarly, water-based varnishes offer durability and a pleasant finish, while also being environmentally friendly. These options ensure that the final product looks professional and holds up well to wear and tear.

Investing in quality materials upfront can lead to long-term savings. For instance, using high-grade paints or finishes may seem more expensive initially but often results in reduced need for reapplication. Additionally, exploring local suppliers or bulk purchasing can provide significant cost reductions. These strategies allow artisans to maintain quality while managing expenses effectively, ensuring that craft items remain attractive and resilient for customers.

FAQS

What are some durable finishes for craft show items?

Durable finishes include polyurethane, acrylic sealants, and epoxy resin, which provide excellent protection against wear and tear while maintaining a visually appealing look.

How can I choose the right finish for different materials?

Consider the material type—wood, metal, fabric, or glass—and select a finish that is compatible. For example, oil-based finishes work well on wood, while spray finishes are often ideal for metal.

What are some best practices for applying finishes effectively?

Ensure the surface is clean and sanded, apply in thin layers, use the right tools (such as brushes or sprayers), and allow adequate drying time between coats for the best results.

Are there budget-friendly finishing options that still look good?

Yes, options like water-based polyurethane, DIY wax finishes, or using spray paint can be cost-effective while still providing a professional appearance and adequate durability.

How do I ensure my finishes are fast-drying?

Choose fast-drying products, work in a well-ventilated area, and apply thin layers to expedite drying time. Always check the manufacturer’s instructions for specific drying times.

Related Links

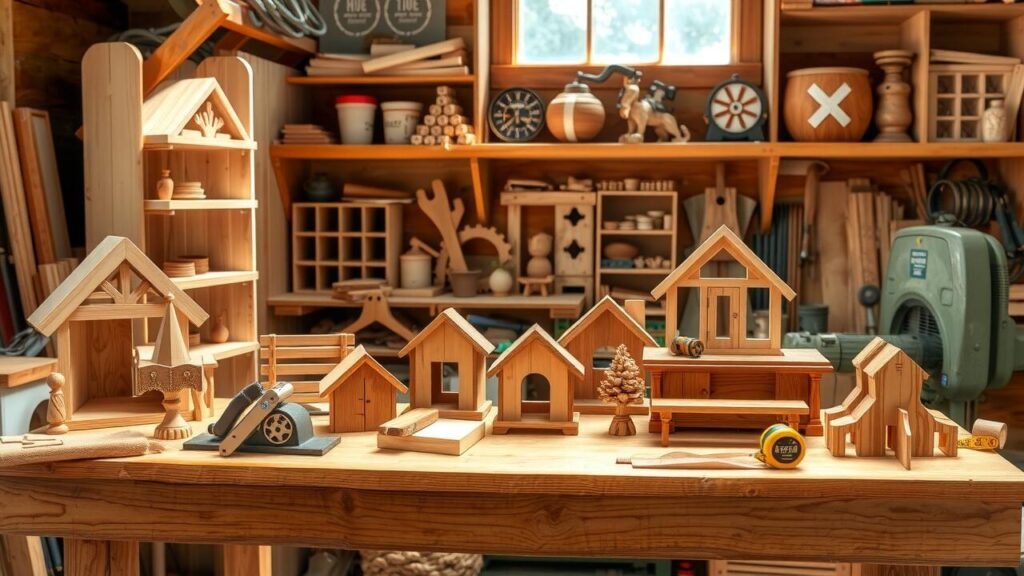

Best Wood Projects That Sell at Craft Shows (And How to Price Them)

Wood Projects That Sell at Craft Shows: Proven Winners + Display Tips

Best Craft Show Wood Items by Size and Price Range

Craft Show Booth Setup for Woodworkers: Simple Layout That Sells

How Much Inventory to Bring to a Craft Show (Easy Planning Guide)

Craft Show Pricing for Wood Items: Tags, Bundles, and Upsells

Packaging Ideas for Wood Products: Make Items Feel Premium

Craft Show Product Mix: Gifts, Decor, and “Impulse Buy” Items

How to Accept Payments at Craft Shows: Simple Tools and Signs

What Sells Best at Holiday Craft Shows: Seasonal Wood Product Ideas

Detailed Blueprints That Guide Every Cut

- Follow step-by-step instructions that don’t skip crucial details

- Get new plans added regularly so you never run out of ideas

- Cut down on costly do-overs with better planning and diagrams