The Importance of Mobility in Small Spaces

Start Building Even Without Fancy Tools

- Follow step-by-step instructions that don’t skip crucial details

- Build at your own pace and grow your skills project by project

- Cut down on costly do-overs with better planning and diagrams

In the realm of small woodworking shops, the ability to move tools and workstations easily can significantly enhance productivity. A fixed workspace limits flexibility and adaptability, making it challenging to tackle various projects efficiently. Mobility allows for quick adjustments according to the nature of the work at hand. This dynamic environment fosters creativity by enabling woodworkers to change their setups with ease.

Having mobile tools and work surfaces also aids in maximizing the use of available space. By incorporating rolling carts or wheeled workbenches, hobbyists can transform their shop to accommodate different tasks and workflows. This adaptability not only improves organization but also helps maintain a clutter-free area, leading to a more enjoyable woodworking experience. Every inch of space matters in a small shop, and mobility can turn those inches into functional, efficient work areas.

Rolling Carts and Portable Workstations

In a small woodworking shop, maximizing space while maintaining functionality is crucial. Rolling carts are an excellent solution for creating a versatile working environment. They can be easily moved around to accommodate different projects or tools. By incorporating storage solutions into these carts, users can organize their materials and tools efficiently, keeping everything within reach while minimizing clutter.

Portable workstations serve a similar purpose, allowing woodworkers to set up their working area wherever needed. These stations can be customized with features such as built-in clamps, tool racks, and adjustable surfaces. A well-designed portable workstation can adapt to various tasks, ensuring that space constraints do not limit creativity or productivity. Such investments enhance flexibility, encouraging more dynamic use of the available workshop space.

Budget-Friendly Materials for Small Shop Projects

When setting up a small workshop, the choice of materials plays a critical role in both the budget and the quality of finished projects. Affordable options such as plywood, oriented strand board (OSB), and reclaimed wood can provide robust solutions that don’t strain finances. These materials often offer the strength and versatility needed for various projects, allowing hobbyists and DIY enthusiasts to create without compromising on durability or aesthetics.

In addition to traditional wood materials, incorporating alternative resources like MDF or particle board can further reduce costs while ensuring functionality. Many small shops can also benefit from sourcing surplus or leftover materials from local businesses or community groups, leading to unique finds that can inspire creativity. Emphasizing efficient use of materials not only reduces waste but also promotes a sustainable approach to woodworking.

Finding Cost-Effective Options Without Sacrificing Quality

Crafting high-quality woodworking projects doesn’t always have to entail a significant financial outlay. Local hardware stores often provide a range of materials that can perform excellently while remaining budget-friendly. Plywood, for instance, is both affordable and versatile, making it a popular choice for many small shop projects. Additionally, reclaimed wood can be an excellent resource; not only does it often come at a lower cost, but it also adds character to the finished product. Keeping an eye on sales and discounts can further enhance the ability to source quality materials without straining the budget.

Another effective strategy is to consider composite materials designed for specific applications. These materials are engineered to offer durability and performance akin to solid wood, but typically at a fraction of the cost. Understanding where to allocate the budget can help prioritize essential components. For example, investing in quality hardware like hinges and drawer slides can make a simpler project appear more refined without necessitating an overall premium on all materials. Emphasizing durability in critical areas ensures longevity while maintaining a professional appearance.

16,000 Woodworking Plans In One Place

- Use exact cutting and materials lists to reduce waste and mistakes

- Build confidently even if you’re a beginner with basic hand tools

- Cut down on costly do-overs with better planning and diagrams

Techniques for Efficient Workspace Layout

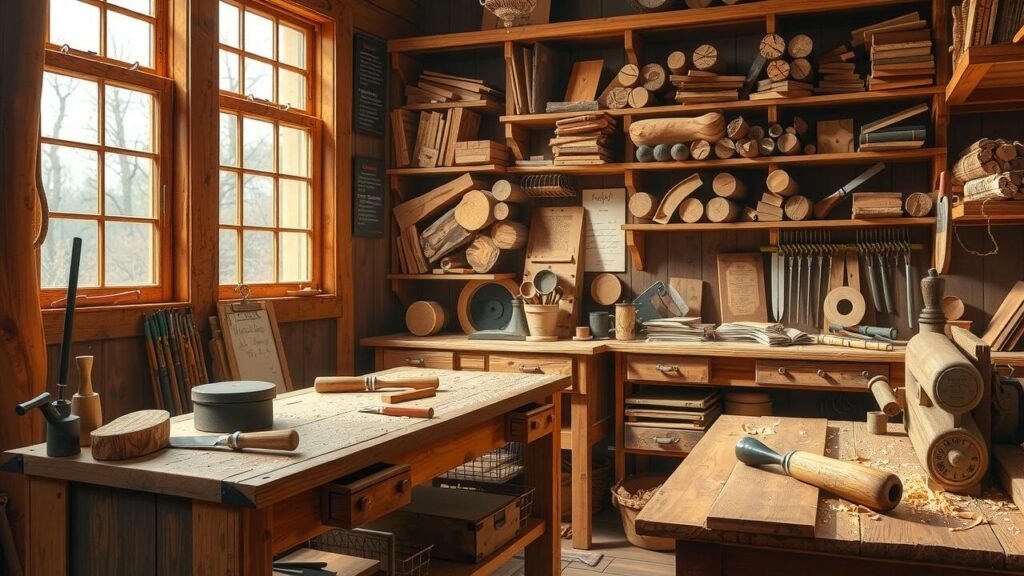

Maximizing efficiency in a small woodworking shop involves a careful arrangement of tools and materials. Start by zoning the space based on the workflow. Designate areas for cutting, assembly, and finishing to create a logical flow. Position frequently used tools within arm’s reach to minimize unnecessary movement. Using pegboards for tool storage keeps them visible and accessible.

Incorporate multi-functional furniture where possible. A workbench with built-in storage can save space while providing essential surfaces. Tall shelving units utilize vertical space effectively, allowing for the organization of supplies without crowding the floor. Maintain clear pathways to ensure safety and ease of movement throughout the workshop. Regular reevaluation of the layout can also help adapt the space to changing needs.

Optimizing Workflow and Tool Arrangement

A well-organized workspace can significantly enhance productivity in woodworking shops, especially those with limited space. Arranging tools and materials efficiently allows for smoother transitions between tasks. Utilize walls and vertical space for storage by installing pegboards or shelving units. Grouping similar tools together reduces the time spent searching for items. Consider a designated area for frequently used tools to minimize disruption during projects.

Another effective strategy involves creating zones for specific tasks, such as cutting, sanding, and assembly. This layout clarifies where to find each tool and reduces clutter. Ensure that your workflow aligns with the natural sequence of your projects. By minimizing the distance between steps, you can work more efficiently and maintain a tidy work environment. Thoughtful planning of these aspects will lead to a more enjoyable woodworking experience.

FAQS

What are some essential features to look for in a rolling cart for a small shop?

When selecting a rolling cart, consider features like sturdy construction, adequate storage space, mobility with smooth-rolling casters, and a design that allows for easy access to tools and materials.

How can I source budget-friendly materials for my woodworking projects?

To find cost-effective materials, check local hardware stores for sales, explore reclaimed wood options, visit online marketplaces, and consider buying in bulk to take advantage of discounts.

What are some effective techniques for optimizing a small workspace layout?

To optimize your layout, arrange tools based on frequency of use, create designated work zones, utilize vertical space for storage, and incorporate movable elements like carts for flexible workflow.

Can I achieve a professional look in my woodworking projects without spending a lot?

Yes, by using high-quality budget materials, focusing on detailed craftsmanship, and applying proper finishing techniques, you can create professional-looking projects without breaking the bank.

Are there specific space-saving woodworking projects ideal for small shops?

Yes, projects such as modular shelving units, foldable workbenches, and multi-functional furniture are excellent space-saving options that can enhance your small shop’s functionality while looking professional.

Related Links

woodworking plans

Best Woodworking Plans: Printable Projects With Cut Lists That Actually Work

Step-by-Step Woodworking Plans PDF: How to Choose Plans You Can Finish

Woodworking Plans Bundle Review: What You Get and Who It’s For

Woodworking Plans for Beginners: Easiest Builds to Start With

Paid vs Free Woodworking Plans: When Paying Saves You Time and Mistakes

Downloadable Woodworking Plans: What a “Good Plan” Always Includes

Most Common Plan Mistakes: Why Builds Go Wrong (and How to Avoid It)

Best Websites for Woodworking Plans: What to Trust (and What to Skip)

How to Read a Woodworking Plan: Cut Lists, Diagrams, and Measurements

Detailed Blueprints That Guide Every Cut

- Follow step-by-step instructions that don’t skip crucial details

- Get new plans added regularly so you never run out of ideas

- Cut down on costly do-overs with better planning and diagrams