Box Joint

Start Building Even Without Fancy Tools

- Follow step-by-step instructions that don’t skip crucial details

- Build at your own pace and grow your skills project by project

- Cut down on costly do-overs with better planning and diagrams

A box joint is a popular woodworking joint known for its strength and simplicity, commonly used in the construction of boxes and drawers. Its interlocking design consists of a series of rectangular cutouts that create a visually striking pattern, which not only adds to the joint’s aesthetic appeal but also improves its structural integrity. This type of joint can be easily fabricated using a table saw or a router, making it accessible for both novice and experienced woodworkers.

Precision is key when creating box joints, as careful measurements ensure a snug fit that resists lateral forces. Proper alignment allows for an even distribution of weight and stress across the joint, which is particularly useful in applications involving heavy loads. The combination of durability and visual interest makes box joints a favorite in both functional and decorative woodworking projects.

Precision and Aesthetics of Box Joints

Crafted with interlocking fingers, box joints not only offer strength but also a visually striking pattern that enhances the overall design of a project. The precision involved in cutting these joints ensures they fit together seamlessly, which contributes to both the structural integrity of the piece and its aesthetic appeal. Woodworkers often highlight the alternating shapes of the fingers as a signature element, attracting attention and elevating the craftsmanship on display.

The versatility of box joints makes them suitable for various applications, from sturdy furniture to decorative boxes. When properly executed, the uniform spacing and clean lines create a polished look that can complement both traditional and modern styles. This combination of functionality and beauty is what makes box joints a favored choice among enthusiasts and professionals alike, demonstrating that practical joints can also be works of art.

Finger Joint

This joint consists of interlocking shapes reminiscent of fingers. Each piece of wood has notches cut into it, allowing the segments to fit together snugly. The design provides an extensive surface area for glue, resulting in a strong bond. It is particularly suited for long grain-to-grain connections, making it an excellent choice for edge-to-edge applications.

In addition to its structural integrity, this joint enhances the aesthetic appeal of woodworking projects. The visible interlocking pattern can serve as a decorative element, showcasing craftsmanship. Its versatility makes it applicable in various furniture pieces and cabinetry, appealing to both functional and artistic considerations in woodworking.

Benefits of Finger Joints in Woodworking

Finger joints are celebrated for their strength, making them ideal for various woodworking projects. The interlocking design provides a larger gluing surface than traditional butt joints, enhancing durability and structural integrity. This feature is particularly valuable in furniture-making where stability is crucial. Additionally, they allow for greater flexibility in the design and construction of furniture elements like drawers and boxes.

Another advantage of finger joints lies in their aesthetic appeal. The unique, zigzag pattern created by the joint adds visual interest to finished pieces, often becoming a design feature in its own right. Craftsmen can showcase their skill through precise cuts, transforming functional joints into beautiful elements of a handmade item. This combination of beauty and strength makes finger joints a popular choice among woodworkers.

16,000 Woodworking Plans In One Place

- Use exact cutting and materials lists to reduce waste and mistakes

- Build confidently even if you’re a beginner with basic hand tools

- Cut down on costly do-overs with better planning and diagrams

Rabbet Joint

The rabbet joint is a simple yet effective woodworking connection where a recess is cut into the edge of one piece of wood, allowing another board to fit snugly into it. This joint is commonly utilized in the construction of cabinets, bookshelves, and frames, as it provides a strong support structure. The depth and width of the rabbet can be adjusted according to the application, ensuring a secure fit and enhancing the overall durability of the assembly.

One of the advantages of using rabbet joints is the ease of alignment during assembly. Since the joint allows pieces to interlock, it minimizes the risk of misalignment, resulting in a more stable finished product. Additionally, this joint can be reinforced with screws or dowels for added strength. Its simple design lends itself well to both novice and experienced woodworkers, making it a popular choice in various woodworking projects.

Understanding Rabbet Joint Applications

Rabbet joints are commonly used in cabinetry and furniture construction due to their ability to create strong connections between two pieces of wood. This joint works particularly well for edges, making it ideal for attaching panels to frames. In situations where a flat surface is needed, such as in bookcases or drawer construction, rabbet joints allow for increased surface area for adhesives while providing structural integrity.

These joints can also be beneficial for aligning multiple pieces of wood. When building boxes or cabinets, rabbet joints offer a seamless look by allowing panels to fit neatly into the grooves. Additionally, they are frequently used in mitered frames, where the rabbet provides a recess for the glass or artwork, enhancing both aesthetics and functionality. This versatility makes them a popular choice among woodworkers seeking durability and visual appeal.

FAQS

What are the nine essential woodworking joints?

The nine essential woodworking joints include butt joint, miter joint, lap joint, dado joint, rabbet joint, finger joint, box joint, dowel joint, and mortise and tenon joint.

Why are woodworking joints important?

Woodworking joints are crucial for the structural integrity and durability of a piece. They help in connecting wood pieces securely and can also enhance the aesthetic appeal of the final project.

How do box joints differ from finger joints?

Box joints feature square-shaped notches that interlock to form strong connections, while finger joints have angled notches that create a larger surface area for gluing, making them particularly useful for long, narrow pieces.

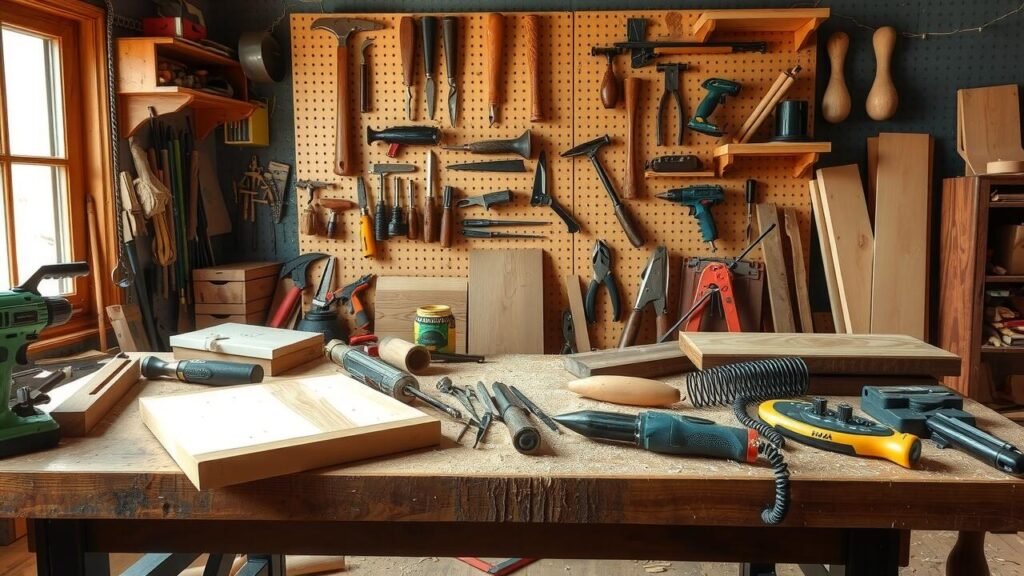

What tools are typically needed to create these woodworking joints?

Common tools for creating woodworking joints include a saw (table saw, miter saw, or hand saw), chisels, clamps, a router, and various jigs designed for specific joints.

Can beginners learn to create these joints?

Yes, beginners can learn to create these joints with practice and the right guidance. Starting with simpler joints like butt and lap joints can help build foundational skills before moving on to more complex joints.

Detailed Blueprints That Guide Every Cut

- Follow step-by-step instructions that don’t skip crucial details

- Get new plans added regularly so you never run out of ideas

- Cut down on costly do-overs with better planning and diagrams